|

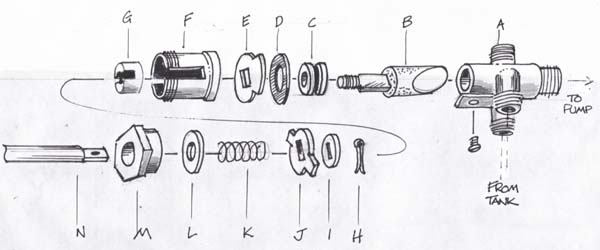

Description of the bits:

A

the main body chromed with the small fine-threaded retaining

screw shown below the main body

B

the diversion valve with cork seal ( 1/8 hole drilled down cork

centre, cork cut at same angle as diagonal flat, then pushed into place

along square section of brass shaft. Cork trimmed to approx. shape with

sharp modelling knife and chucked and filed using a crisp new 2nd-cut

file, finished to tight fit inside A with 320 grade paper. Ensure

sufficient square shaft exposed to engage C,D, E and F

C

grooved brass retaining collar, circular centre hole fits loosely

on square section of B, held in place by that fine screw under A

body.

D

fibre washer (to help seal valve), followed by thin plate E which

limits rotary movement of valve by abutting protrusion on body of A.

F

chrome barrel engages square brass end of B, and is retained

by circular threaded nut G.

The shaft N, which is connected to the cockpit control is then threaded

with chrome end M, steel washer L (which fits inside M), the fine

compression spring K, and finally the eared toggle J and washer

I . Both J and I have a slot which engages the flat end tongue

on the rod N, and are retained by fine split-pin H.

Final assembly: The rod and its assembly with the ears of J engaging

the slotted section of F

the chromed end nut M securing the rod

in place by screwing onto F. Ive made it sound worse than it really

is! Its fiddly but quite simple when laid out on the bench. Dont know

about soaking the cork seal in oil

open to suggestions by those more

qualified.

|