René Thomas first supplied steering wheels to the Morris Garages of Oxford changing to ones from Bluemel Bros. Ltd. later on. Both suppliers provided a similar steering wheel using the spring spoke design to minimize "road and engine" vibration according to early advertisements. Some of these wheels had a ribbed design to simulate the popular cord wrapping preferred by the enthusiast. The T-series steering wheels were manufactured by Bluemel Bros. of Wolston, Warwickshire near Coventry after Bluemels became the works supplier in the mid 1920s at about the time "Old No. One was constructed by Cecil Kimber.

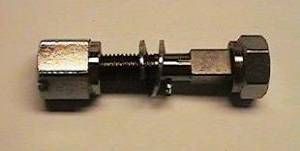

The original MG T-series steering wheels can be divided into two broad types, fixed and adjustable. A 17" non-adjustable steering wheel held onto the steering shaft with a keyway and bolt was found on the TA roadster series up to chassis No. 2881. This was followed by an adjustable steering wheel fitted to the TA beginning with chassis No. 2882. The adjustable wheel was always on the Tickford and rare coupé version, although of a slightly different design than that of the roadster. The wheel is positioned on the steering shaft by multiple splines and held in place with a clamp bolt of a distinctive design. The fore and aft movement is approximately 3.5"; vertical movement is approximately 2". Both wheels are 17" in diameter, 3 spoked and black in color.

The Bluemel brothers, Frank and Douglas, moved to a new "greenfield site" in 1904 as it was near Coventry, at that time the center of British cycle manufacture and eventually auto manufacture. Bluemels Bros. was an accessory manufacturer of car and cycle accessories and worked in a new Bakelite material, cellulose acetate (Celluloid). Hubs for the non-adjustable TA setup were sand cast from brass or aluminum at the works. The adjustable hub castings were of high quality aluminum before World War II, however after the war years, scrap aluminum was used when supplies were uncertain and these hubs can be brittle or prone to cracking at the pinch bolt area. The rest of the wheel construction was in light gauge rolled steel with mild 18 gauge steel spokes.

TB production and most of the TC production used the all black wheel. This wheel is the Douglas A.S.W. (Adjustable Steering Wheel) but is more commonly called the "home market" wheel and is of one-piece construction. It is covered in a plastic material thought to be Bakelite but is technically a celluloid material. These wheels can show signs of stress failure or breakage at the point where the spoke and rim attach accompanied with flaking of the black celluloid covering. This wheel was produced Nov. 1938 to Nov. 1949.

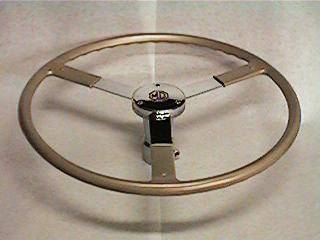

In the fall of 1948 another type of adjustable steering wheel was introduced on the TC consisting of a ½ chrome spoked wheel in a color referred to as "gold pearl." This wheel was found most usually on the export cars to North America but was also found on a limited number of cars destined for other parts of the world and the home market as well. It was injection molded in a swirled pattern achieved by using different viscosity colors. The material proved to be unstable with temperature and UV light and perished after a few years of use. The chrome was a flash plating over the steel spoke, also prone to flaking off after a few years. The hubs are of good quality aluminum and can be detached from the spoke/rim assembly. This wheel was available Oct. 1948 to the end of TC production in Nov. 1949.

In the early 1950s, a ½ chrome black rim in exactly the same pattern as the gold pearl and originally for use on the Aston Martin DB2, was made available for replacements. These rims were available from 1952 and onward. By substituting the black Aston Martin rim, the export hub could be used for many more years. A few of these rims are still serviceable into the new millennia with only minor cracking as the black injection molded plastic was more stable than the gold pearl formulation. It is possible this is the "bare steering wheel" that has been listed with a different part number in the BMC parts list, No.AKD 856

An important thought to remember is the austere economic condition in England immediately after the war and the periodic shortages in materials. The factory in Abingdon produced many cars under this situation and when supplies ran low substitutions would be made in order to finish up cars for sale. It is not surprising to find a broad range of "original" configurations for the cars. The production line would not be held up for lack of an export wheel if a home market wheel could be fit, or the other way around as well.

Along with the austere conditions, these cars were built to a price. The overall level of fit and finish was good yet component parts were procured at a low price. Original steering wheels were inexpensive and were often replaced after a few seasons of use with after market wheels of better construction and finish. Very few original and undamaged steering wheels exist of either "original" design to the present day. A good example of a very common replacement wheel is the Brooklands 4 spoked wheel manufactured by Bluemel Bros Ltd., the same supplier of the "original" wheel.

The Brooklands wheel was named for the racecourse in Weybridge, Surrey and implied a "sporting" heritage. Several colors were available in solid and marbled finishes; the T-series cars used an adjustable hub with fixed hubs available for other cars. One of the four spoke separators often had the patent date on the backside and one other had a Bluemels logo with feather in blue cloisonné or enamel. The application was not limited to MGs or even autos; some Brookland wheels were built for nautical craft as well. The Brooklands design has gone through several permutations over the years and the results are a bewildering assortment of diameters, spoke separators, hub designs, clamping arraignments, etc. These wheels were a stronger design, with the 4 sets of stainless steel spokes versus the 3 flat spokes originally found. Unfortunately, the mottled and lighter colors were prone to the same decay that plagued the export gold pearl steering wheel.

The archaeology of these steering wheels was based on an examination of dozens of the T-series steering wheels and after market wheels along with research into the early MG production and the Bluemel organization. I hope it is of interest to the reader, and as with other details of the MG T-series cars, subject to additions and changes as additional records are discovered. Ben Cordsen, 2003

Douglas/home market wheel

Back of the Douglas/home market wheel with 15 finger indents per segment

The correct clamp bolt

Export gold pearl wheel

Rear of the Export gold pearl wheel with 14 finger indents per segment

The "lever" clamp bolt

Black rimmed export wheel, see text

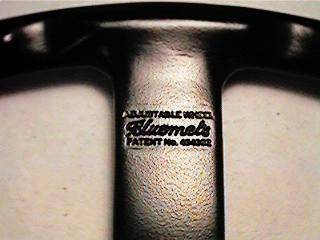

Logo/patent information, export

Bluemels Logo on Douglas/home market wheel

Douglas "A. S. W." patent pend. on home wheel

Pantograph engraved chrome center medallion, red or bronze filled with 4 BA oval head screws

Rear of an early TA steering wheel, no finger indents

Early TA wheel medallion detail

All of the above photographs are of a wheel that would have been mounted to chassis number TA 2881 or before using the non-adjustable steering shaft.