Fitting a New Rear Axle Oil Thrower without

Dismantling the Axle

Cliff Knight

Whilst driving in the Greek mountains this year (2008) I had the misfortune to break 2 studs and loose the remaining 4 nuts that hold the rear brake drum and hub to the bearing housing on one of the rear wheel. I managed to stop the car, but not before the wheel with half shaft and brake drum still attached had parted company with the diff and was sticking out about 12 inches. I managed a roadside repair by fitting 3 nuts from the good side to 3 of the remaining studs and taking the bends on the mountain tracks at a more sedate speed.

When I got home and stripped the parts down to do the repairs I found that the oil thrower bush had suffered badly. A large quantity of brass swarf was evidence that the thrower had been acting as the only bearing supporting the weight of the car on that side for the short time it took me to stop.

The problem was how could I get the bush out without dismantling the entire axle to get some sort of extractor to the inside edge of the thrower.

Well my solution, only valid for those wishing to fit a new thrower without dismantling the diff, is as follows:

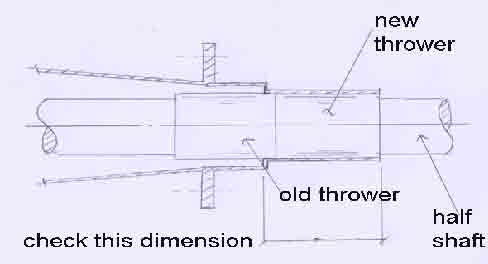

Check the depth of the smaller diameter of the axle case that the thrower sits on. You should find that it is at least .125 longer than the bush. Push the old bush into the axle the same dimension as the length of the new one. Push the new one in flush with the end of the axle tube. The old bush will do no harm acting in unison with the new one and located by the 0.125in or so of interference fit in the housing.

There are several options for driving in the bushes. I used a good fit brass pusher and the wheel mallet. A better alternative may be to improvise a pusher using the brake back plate flange and some long bolts. In any event don’t hammer the bush directly.

Sketch below shows the arrangement:

|